Innovation In Sustainability

How serious are we about sustainability?

We’re at the forefront of our industry in innovation for environmentally responsible packaging and we apply this to everything we do, the bottles we manufacture, our processes, operations and logistics, raising the standard and leading the way.

We’re closing the loop from plastic bottles to recycled resins to plastic bottles again. Utilising PCR – Post-Consumer Recycled Plastic – which is derived from an end product (such as a milk or water bottles) that has completed its life cycle as a consumer item and would otherwise have been disposed of as a solid waste product. Post-consumer plastics include plastics that have been collected in commercial and residential recycling programs.

For example, that plastic milk bottle you threw into your curb-side recycle bin? Instead of going to a landfill, it goes to a recycling centre where it is processed and reconstituted back into plastic resin material. We then turn it back into plastic bottles again.

There is another type of recycled content that is termed post-industrial. This is the practice of using your own internal scrap back into regular production. At Forward Plastics, we have always done this from the very beginning as a part of our typical manufacturing process adding up to 50% of post-industrial recycled resin into our products.

We’re re-using New Zealand milk bottles to manufacture multi-layered plastic containers

Multi-Layer Co-Extrusion Process

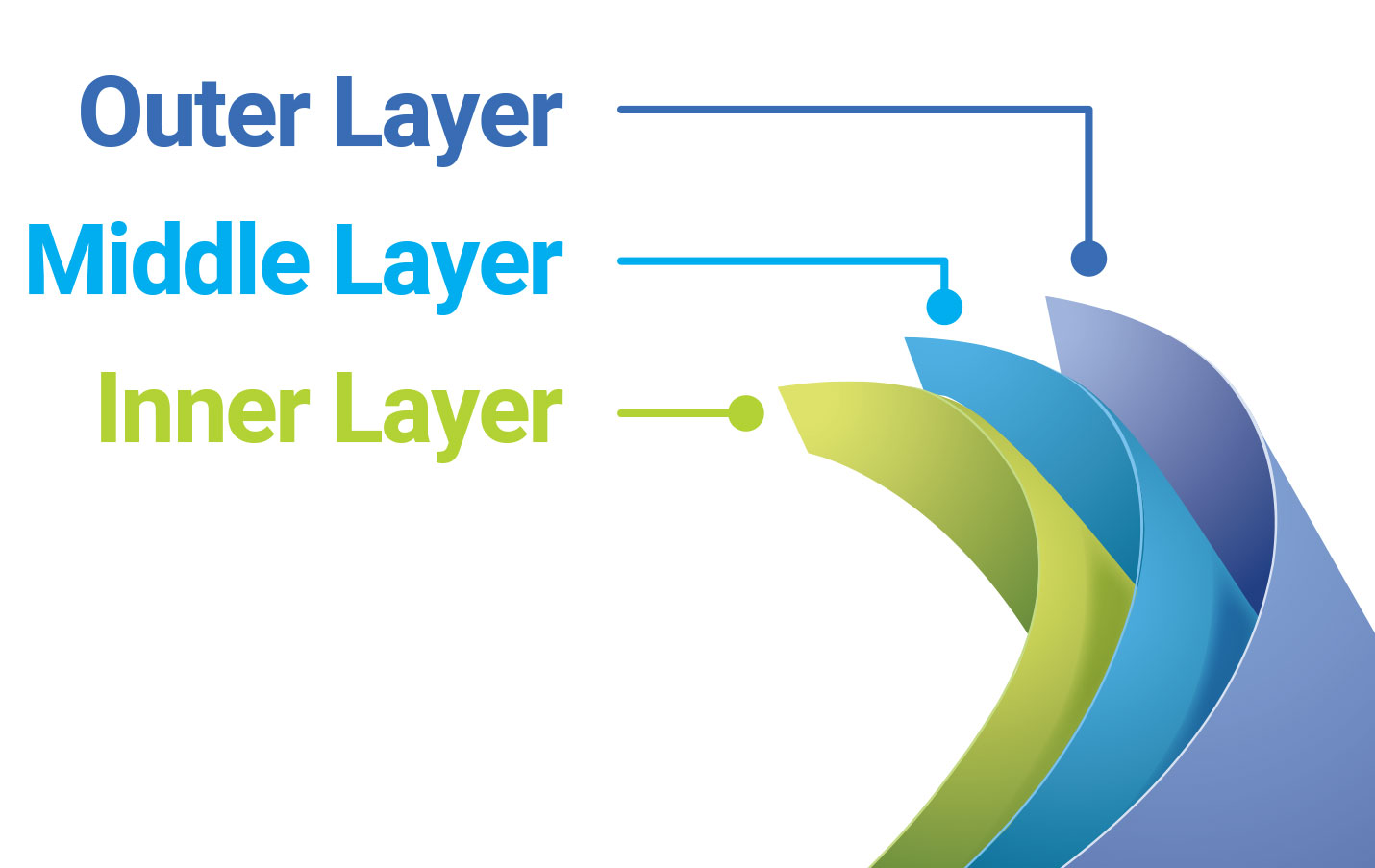

The term co-extrusion refers to the technology used to make containers that contain multiple layers in their wall structures. The layers may be made of the same or different materials, coloured or uncoloured material or recycled or virgin materials.

Co-extrusion technology, while not new, is gaining momentum in the industry with the ever-increasing push to provide solutions in sustainability around plastic packaging. Presenting a great opportunity for the inclusion of recycled material in the middle layers, our modern multi-head co-extrusion machines are designed just for this.

We are currently involved in a number of innovative and exciting new projects including the addition of a middle layer of 100% post-consumer recycled material sourced from reclaimed New Zealand milk bottles, to our bottles and containers. These products enable us to reuse plastic from the recycling streams back into a multi-layered container without compromise to top load strength or outer layer surface finish, and with suitable chemical resistance to a variety of products. Best of all, these multi-layer bottles are again fully recyclable!

Our commitment to the environment also sees us actively working towards the development of other products and processes with increasing amounts of post-consumer recycled resins, just another part of the “reduce, re-use, recycle” equation fundamental to the Forward Plastics ethos.

Bio-Based HDPE (Sugarcane Plastic) – Plant-Based, Sustainable, Renewable & 100% Recyclable

Bio-Based PE

Forward Plastics manufactures premium bio-based, plant-based HDPE packaging made from sustainably grown sugarcane. This renewable resin is a direct alternative to traditional fossil-fuel plastics and delivers identical strength, durability and performance, while significantly reducing the carbon footprint of your packaging.

What is Sugarcane-Based Plant-Based Plastic?

Bio-HDPE (also called plant-based plastic, sugarcane plastic, or renewable HDPE) is produced from sugarcane ethanol instead of oil. Because sugarcane absorbs CO₂ as it grows, this material provides a genuine low-carbon, renewable packaging solution for brands wanting credible sustainability benefits.

Key Benefits of Bio-HDPE (Plant-Based HDPE)

✔ Renewable, plant-based material made from sugarcane

Sourced from fast-growing sugarcane crops – an annually harvested renewable resource.

✔ Lower carbon footprint

Sugarcane naturally captures CO₂ during growth, helping to reduce greenhouse gas emissions across the entire packaging lifecycle.

✔ Same performance as traditional fossil-fuel HDPE

Bio-HDPE is chemically identical to conventional HDPE, making it a true drop-in replacement with no compromise in quality or processing.

✔ 100% recyclable in New Zealand (Recycling Code 2)

Unlike other plant-based plastics that require specialised facilities, sugarcane HDPE is fully compatible with New Zealand’s existing HDPE recycling streams.

✔ Ideal for FMCG & household brands

Perfect for cosmetics, personal care, food, cleaning, household, industrial and commercial packaging.

Why Brands Are Switching to Plant-Based Packaging

Choosing plant-based, renewable polyethylene allows brands to:

- Reduce reliance on fossil fuels

- Lower carbon emissions

- Tell a transparent sustainability story backed by real science

- Maintain supply-chain reliability and product performance

- Make the shift without changing tooling, moulds or production processes

Forward Plastics uses certified bio-based HDPE (“I’m Green™” resin by Braskem) to manufacture bottles, closures and packaging for leading New Zealand brands seeking more sustainable material options.

A Renewable Packaging Option with Real Climate Impact

Bio-based HDPE combines the best of both worlds:

- Renewable and plant-derived, reducing dependence on fossil fuels

- 100% recyclable, fitting seamlessly into New Zealand’s mainstream recycling systems

- High performance, meeting the same specifications and durability expectations as petrochemical HDPE

This makes it one of the most practical and credible sustainable packaging solutions available today.